Advancing Silicon Photonic Development with Wave Photonics Process Design Kits

Silicon photonics (SiPh) holds enormous potential to transform industries ranging from telecommunications and data centres to medical diagnostics and environmental sensing. However, the promise of SiPh can only be realised if there is sufficient technological access and the sophisticated process required for its commercial deployment are simplified.

Overcoming variations in manufacturing and ensuring consistency in performance are critical hurdles that must be addressed. Against this backdrop, Wave Photonics aims to offer a practical solution. Over the past few years, Wave Photonics’ work, supported by CORNERSTONE, has steadily helped advance access to SiPh by developing dependable, high-performance Process Design Kits (PDKs) that mitigate manufacturing inconsistencies while expediting the overall development timeline.

The Role of CORNERSTONE

CORNERSTONE’s contribution to this collaboration has been both foundational and ongoing. Operating with a clear, structured process and an openness to supporting small-scale projects, CORNERSTONE has provided an accessible platform through which pioneering SiPh designs can be rigorously tested and validated.

“What really sets CORNERSTONE apart is how accessible and transparent they are. You know who to talk to, the process is clear, and even if there are delays, you’re never left wondering. It’s not something you get with a larger fab—where you often need significant funding and deep experience just to get started.”

James Lee, Co-Founder, Wave Photonics

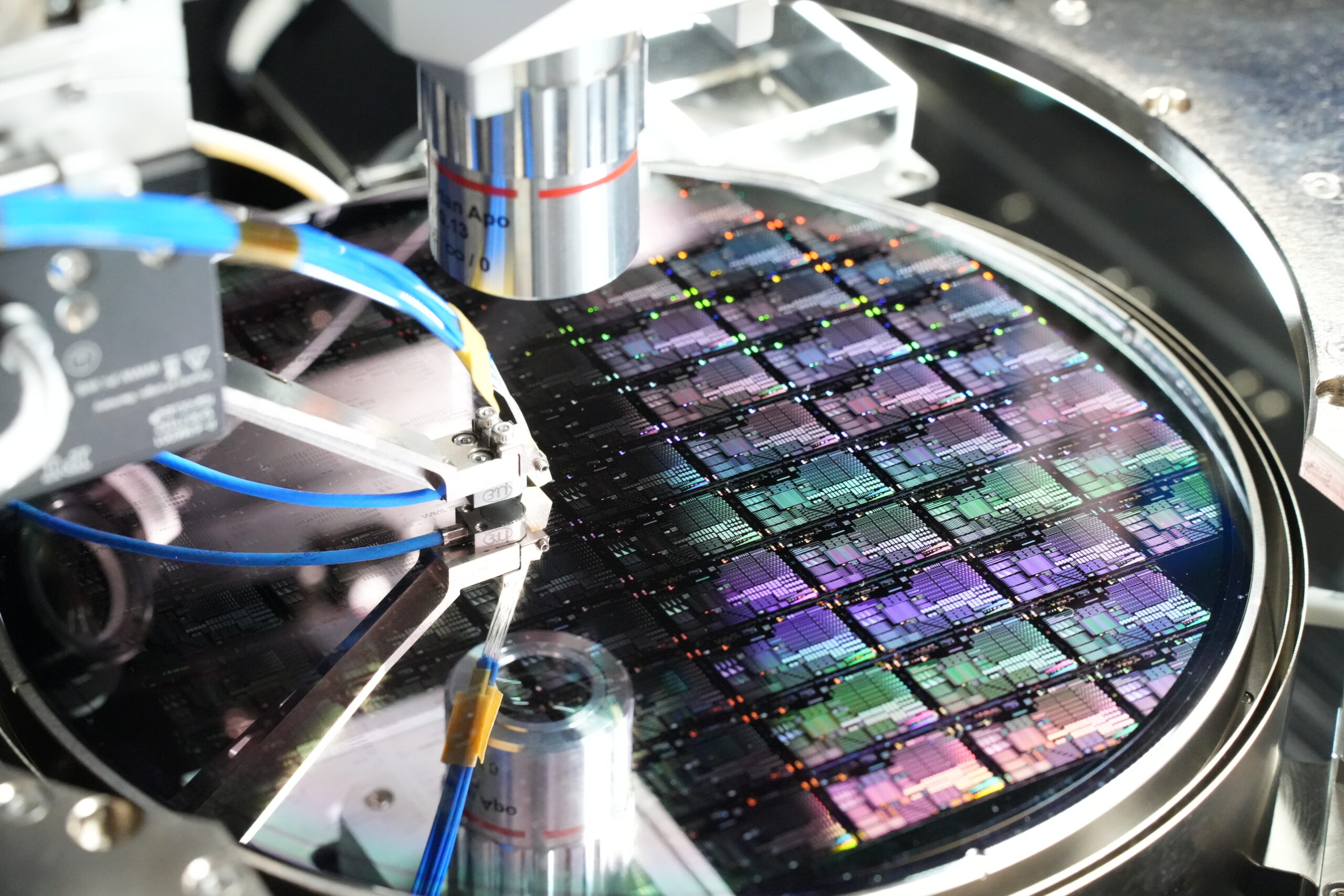

Its multi-project wafer approach offers a low barrier to entry – an essential feature for companies like Wave Photonics that are breaking new ground on limited budgets. The foundry’s capacity to deliver multiple rapid iterations of wafer runs has enabled the necessary data sharing and feedback loops critical for refining complex computational models that underpin Wave Photonics’ PDKs. This synergy accelerates the development cycle and ensures that the resulting technology is robust enough for high-volume production, setting a new standard in the SiPh sector.

The Wider Impact of Collaboration

The initial partnership between Wave Photonics and CORNERSTONE began early in Wave Photonics’ history and helped to lay the groundwork for its PDK development. This process involved using CORNERSTONE’s multi-project wafer (MPW) services to thoroughly test and verify its computational models. Real-world fabrication feedback proved essential in refining design performance and ensuring the PDKs could reliably handle manufacturing variation – an issue that typically hampers SiPh scalability and yield.

“CORNERSTONE has played a key role in enabling our technology. The multi-project wafer service gave us the ability to validate our models in a real fabrication setting, and the openness to share data has been vital. Without that access and collaboration, we wouldn’t have been able to prove our approach to PDK development.”

James Lee, Co-Founder, Wave Photonics

By leveraging CORNERSTONE’s cost-effective, low-barrier access to fabrication, Wave Photonics has demonstrated how sophisticated modelling can translate into production-ready design kits that perform well at scale. This is particularly notable when compared to standard PDKs, which often fall short under high-volume conditions.

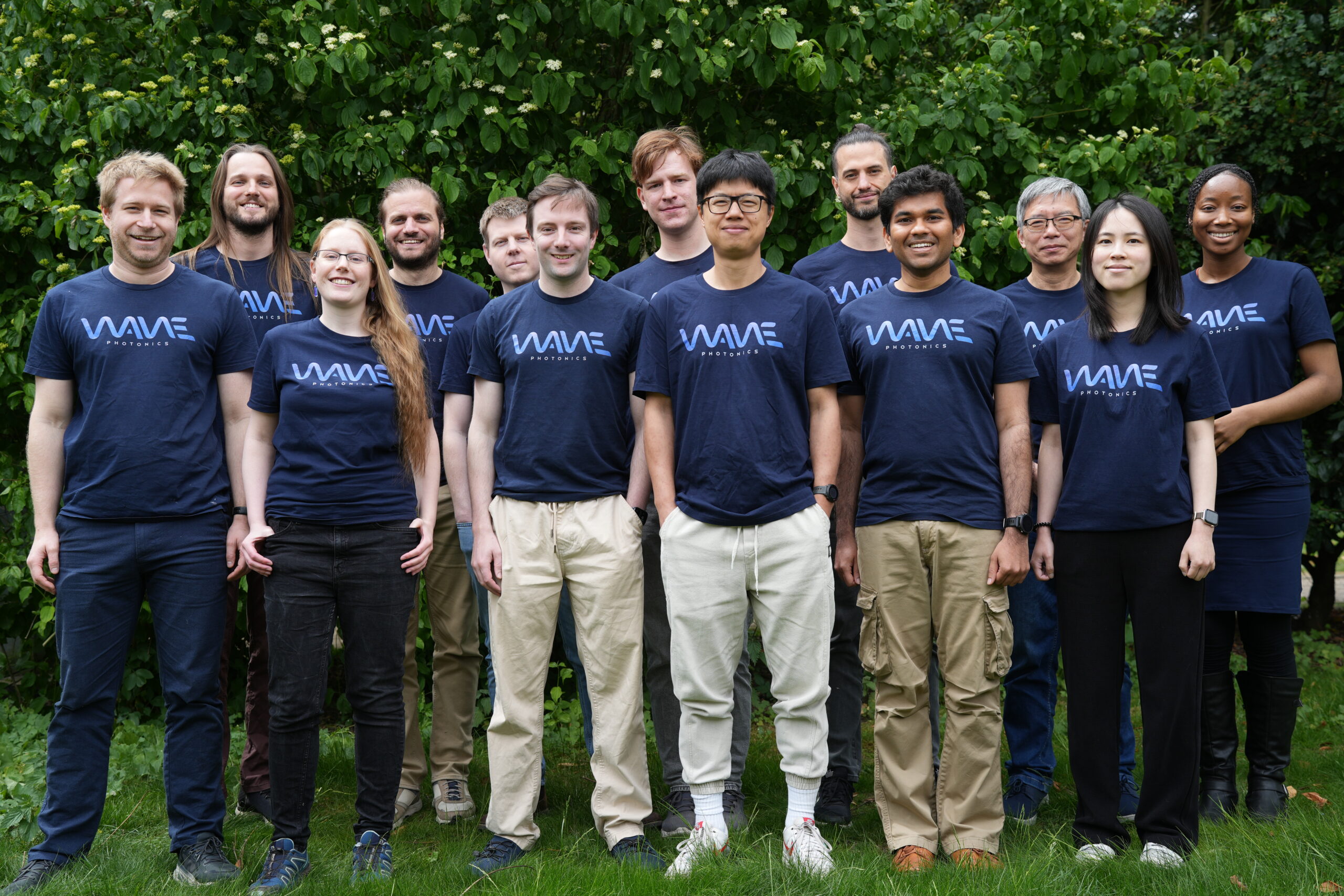

Beyond conventional SiPh applications, Wave Photonics sees a future opportunity in sectors such as medical diagnostics and environmental sensing, where rapid prototyping and adaptability are vital. Having grown from a small start-up into a 16-person team, the company is now well positioned to accelerate SiPh development and adoption – with CORNERSTONE continuing to play a key supporting role.

Wave Photonics: Driving High-Yield SiPh Production

Wave Photonics leverages its proprietary design technology to develop comprehensive, state-of-the-art PDKs for a broad range of applications, helping to improve the development and, therefore, adoption of SiPh. Each PDK includes fabrication-aware scattering parameters (S-Params) for full photonic circuit simulation and works seamlessly with leading design environments such as GDSFactory, Luceda IPKISS, Cadence Virtuoso, Siemens L-Edit and with several more integrations coming soon.

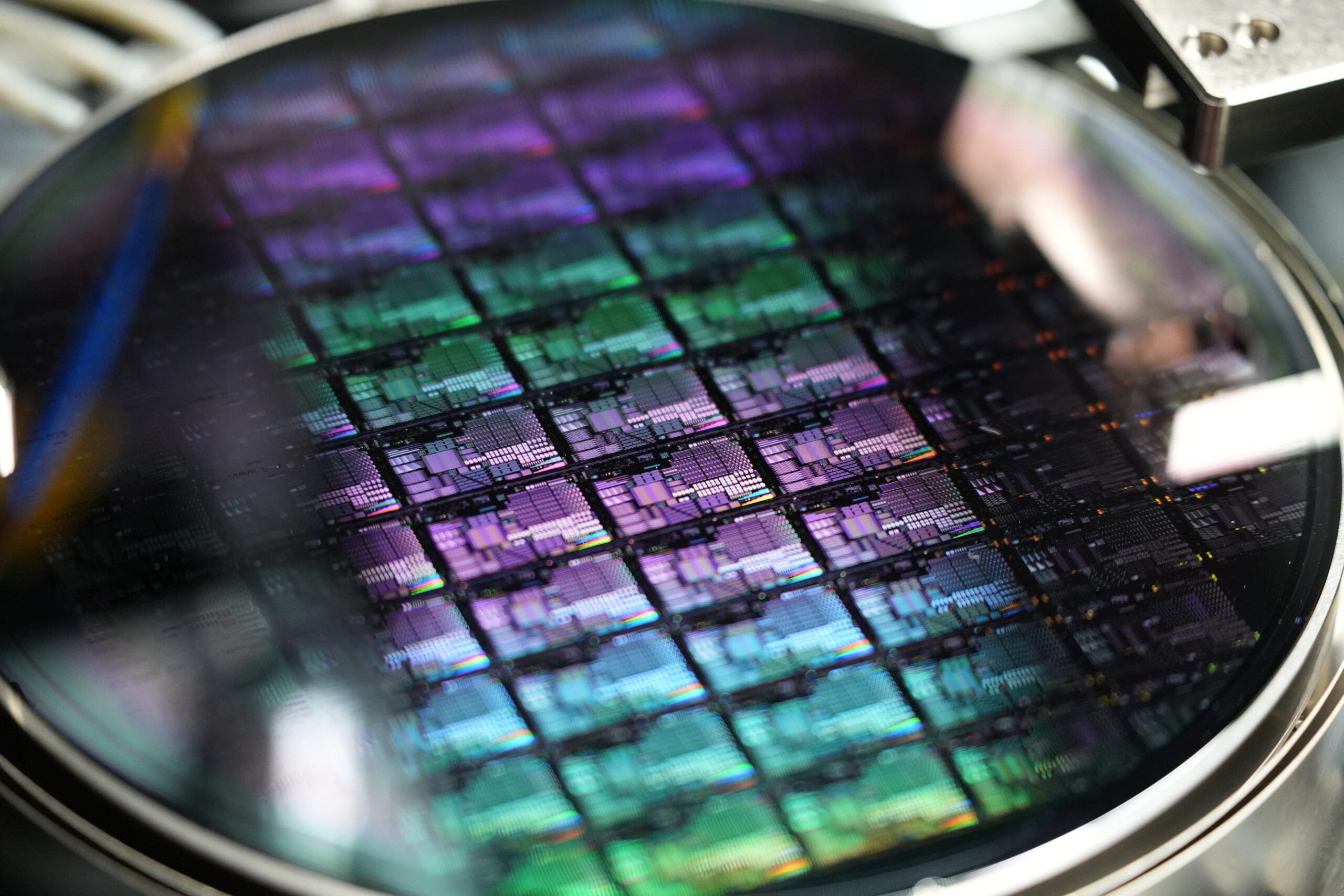

Through the Innovate UK-funded Silicon Nitride for Quantum (SiNQ) project, Wave Photonics worked alongside CORNERSTONE, as well as Oxford Ionics, and the Compound Semiconductor Applications (CSA) Catapult. This project resulted in a new visible-wavelength silicon nitride process and the world’s most expansive photonics PDK, spanning 33 wavelengths from 493 nm to 1550 nm.

Validated using measured wafer-scale data from CSA Catapult, the SiNQ PDK demonstrated a 2× improvement in component performance uniformity compared with conventional inverse-designed components. This level of predictability is crucial in quantum applications, where variation-sensitive wavelengths and tight optical tolerances often demand multiple design iterations.

The SiNQ process and PDK are now available through CORNERSTONE’s open-access foundry platform, with the first MPW run happening in the second half of 2025, helping to support the development of scalable quantum, sensing, and AR/VR photonic systems.

For telecommunications, the Telecoms-band PDKs cover multiple wavelength bands, offering a streamlined path to packaged devices using the company’s QPICPAC service. These advanced solutions are made accessible through CORNERSTONE’s foundry platform, cementing a robust pathway from research to commercial deployment. Furthermore, Wave Photonics offers rapid custom PDK generation for demanding sectors including AI data centres, gas sensing, and satellite communication, with materials such as thin-film lithium niobate, aluminium oxide, gallium arsenide, and various others available.

Wave Photonics Team

Conclusion

This working partnership highlights the transformative potential of combining computational innovation with structured industrial processes. By addressing manufacturing imperfections head-on, the company aims to chart a course towards a new era in SiPh – one where it is possible to design mass-production-ready SiPh devices in the virtual world.

Building on the success of its existing foundry, the CORNERSTONE Photonics Innovation Centre (C-PIC) is already providing enhanced packaging support, application expertise, training resources and an ecosystem of online tools. Together, C-PIC, including the CORNERSTONE foundry, continues to support Wave Photonics in scaling their technology platform and removing persistent barriers to wider SiPh adoption.