Transforming Ideas into Innovation: Hands-On Silicon Photonics Training at CORNERSTONE

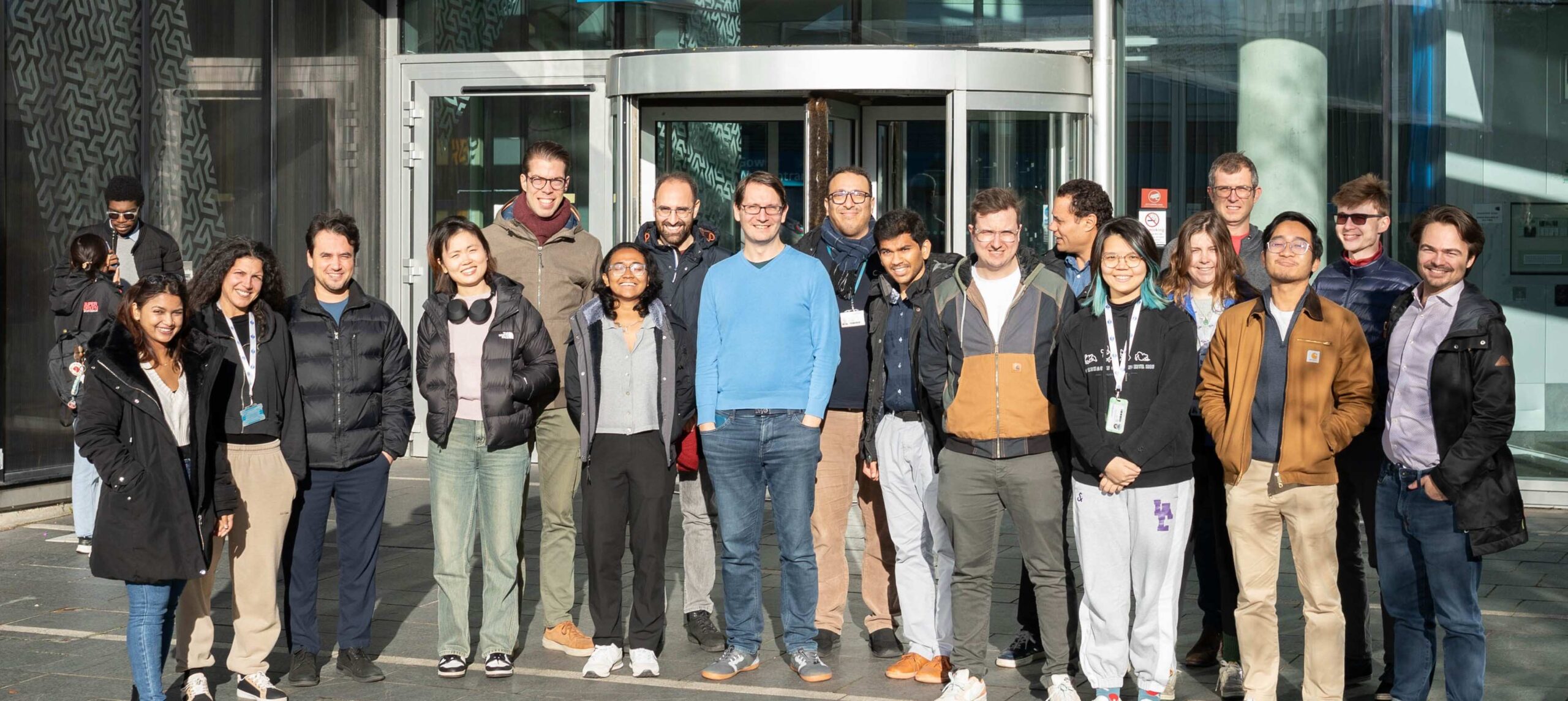

In the month of November, CORNERSTONE welcomed participants from diverse industries to its three-day PhotonHub Experience Centre course: Silicon Photonics – Build Your Own Thermo-Optic Modulator.

Hosted at the University of Southampton, this immersive event introduced both beginners and experienced professionals to the intricate world of silicon photonics fabrication.

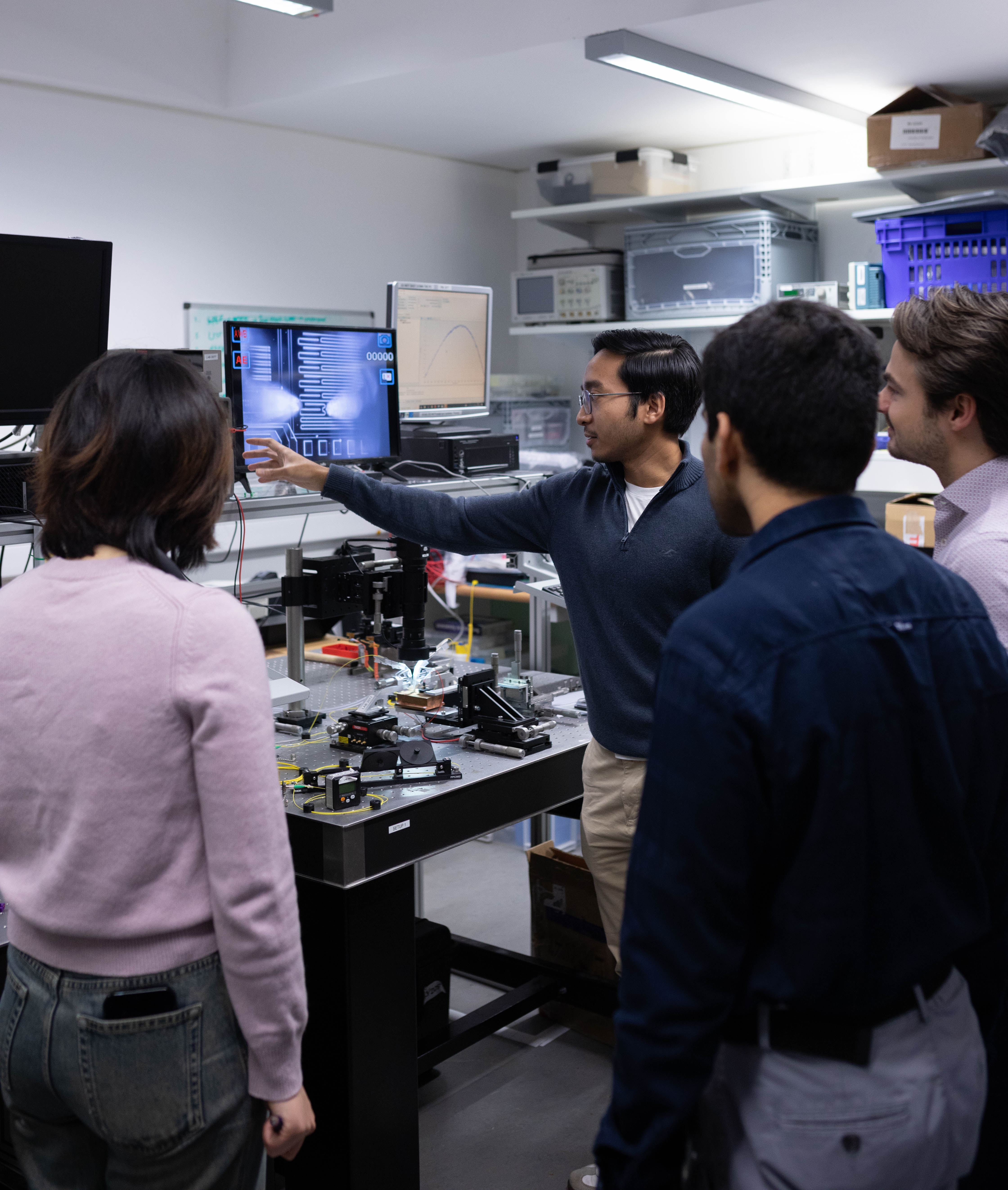

From the moment participants donned their cleanroom suits and stepped into our state-of-the-art fabrication facility, the excitement was palpable. Designed to teach the principles of silicon photonics while offering hands-on experience, the course proved to be a transformative journey for all attendees.

“Walking into the cleanroom and working on these processes myself was incredible,” said Qi Tang, one of the attendees. “The CORNERSTONE team was so open and supportive, answering every question in detail and guiding us through tutorials. Seeing the tools in action and understanding the tolerances involved has given me a new perspective on how photonics devices are brought to life.”

The training covered six key technology areas critical to silicon photonics fabrication:

The training covered six key technology areas critical to silicon photonics fabrication:

- Deep-UV Projection Lithography – translating designs into photosensitive resist layers.

- Silicon Waveguide Etching – defining the pathways for light.

- Cladding Deposition – adding protective and functional layers.

- Metallisation – ensuring precise electrical connections.

- Dicing – preparing individual photonic chips.

- Wafer-Scale Testing – ensuring the quality and performance of fabricated devices.

Each day was structured to combine engaging lectures, detailed demonstrations, and hands-on activities. On the first day, participants were introduced to cleanroom protocols and the foundational principles of silicon photonics, seamlessly transitioning into initial fabrication steps like Deep-UV lithography and waveguide etching.

The second day advanced into processes like cladding deposition and metallisation, where participants learned how to build and refine layers. By the third and final day, attendees were fully immersed in wafer-scale testing and dicing—culminating in a comprehensive understanding of the fabrication pipeline. Each stage was carefully designed to ensure accessibility for beginners while challenging more experienced attendees to deepen their knowledge.

“I found the experience incredibly valuable,” shared James Banyard, another participant. “Seeing the process up close and step-by-step really reinforced the fabrication concepts that were presented. Talking with the experienced technicians and engineers added depth and insight that you just can’t get from online resources.”

Throughout the course, the Cornerstone team emphasized collaboration and curiosity. Attendees were encouraged to ask questions, discuss ideas, and share challenges they’ve faced in their own fields. The result was a dynamic learning environment where knowledge flowed freely between participants and instructors.

“The fabrication support CORNERSTONE offers is truly powerful and invaluable,” Qi Tang reflected. “I can already see how what I’ve learned here will help bring my photonics ideas into production.”

The highlight of the course? Each participant left with their own fabricated silicon photonics chip—a tangible reminder of what they’d accomplished.

A Testament to the Power of Practical Learning

At CORNERSTONE, we believe that hands-on experience is the most effective way to demystify complex technologies. This course was a testament to that belief, combining approachable guidance with industry-leading expertise to deliver a transformative learning experience.

We are immensely proud of the positive impact this course had on its participants and look forward to continuing to empower innovators, researchers, and entrepreneurs in the field of silicon photonics.

If you missed this session, don’t worry—there will be more opportunities to join us in the future. Stay tuned for announcements about our upcoming training events and initiatives.

Together, let’s shape the future of photonics innovation.